THE BURL TREE

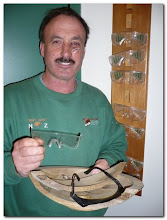

THE BURL TREEI think the burl branch is red beech, but

I am not sure. The plan was simple -

make each of the eight burrs into a

small bowl and leave them still attached

to the tree. The operation was not so

simple.

The work is mounted onto what I call

the slide and this is moved around on

the MDF flywheel which is attached to

a 150mm face plate. I levelled and

secured the wood into the position I

required with the aid of wedges and hot

melt glue. The straps are an extra

precaution. The whole device is then

balanced with strategically placed

lumps of lead securely attached.

For each of the eight bowls the log was

re-attached and re-balanced. On

occasions I had difficulty getting the chisel down between two burls and

changes of shape were needed. When I came to do the burl on the bottom

end I didn’t have enough swing and had to cut 100mm off the other end.

The ninth bowl on the very top was turned last between centres. Some

carving was then needed to blend the cuts between bowls and restore

shape to the slimmed down branch. Airbrushing highlighted the texture

on the tree.

The burl which serves as the base was scribed around the base of the burl

tree. As this piece stands 600mm high it needed something to give it

stability.

Please note that attempting a piece like this can be rather daunting unless

you understand how to balance the work. My lathe weighs 650kg and is

bolted to the floor. This helps, but if any vibration is felt, you haven’t

spent enough time getting it balanced.

Oh, by the way, on the Monday I had to go and buy some more trailer

tie-downs as they were a bit short after this exercise. I am proud to say

this piece now sits alongside 250 others in a private collection in Hong.

Go To I think the burl branch is red beech, but

I am not sure. The plan was simple -

make each of the eight burrs into a

small bowl and leave them still attached

to the tree. The operation was not so

simple.

The work is mounted onto what I call

the slide and this is moved around on

the MDF flywheel which is attached to

a 150mm face plate. I levelled and

secured the wood into the position I

required with the aid of wedges and hot

melt glue. The straps are an extra

precaution. The whole device is then

balanced with strategically placed

lumps of lead securely attached.

For each of the eight bowls the log was

re-attached and re-balanced. On

occasions I had difficulty getting the chisel down between two burls and

changes of shape were needed. When I came to do the burl on the bottom

end I didn’t have enough swing and had to cut 100mm off the other end.

The ninth bowl on the very top was turned last between centres. Some

carving was then needed to blend the cuts between bowls and restore

shape to the slimmed down branch. Airbrushing highlighted the texture

on the tree.

The burl which serves as the base was scribed around the base of the burl

tree. As this piece stands 600mm high it needed something to give it

stability.

Please note that attempting a piece like this can be rather daunting unless

you understand how to balance the work. My lathe weighs 650kg and is

bolted to the floor. This helps, but if any vibration is felt, you haven’t

spent enough time getting it balanced.

Oh, by the way, on the Monday I had to go and buy some more trailer

tie-downs as they were a bit short after this exercise. I am proud to say

this piece now sits alongside 250 others in a private collection in Hong.

See http://www.timberly.co.nz/terry_articles.htm

For pictures of how I held this piece on the lathe

No comments:

Post a Comment